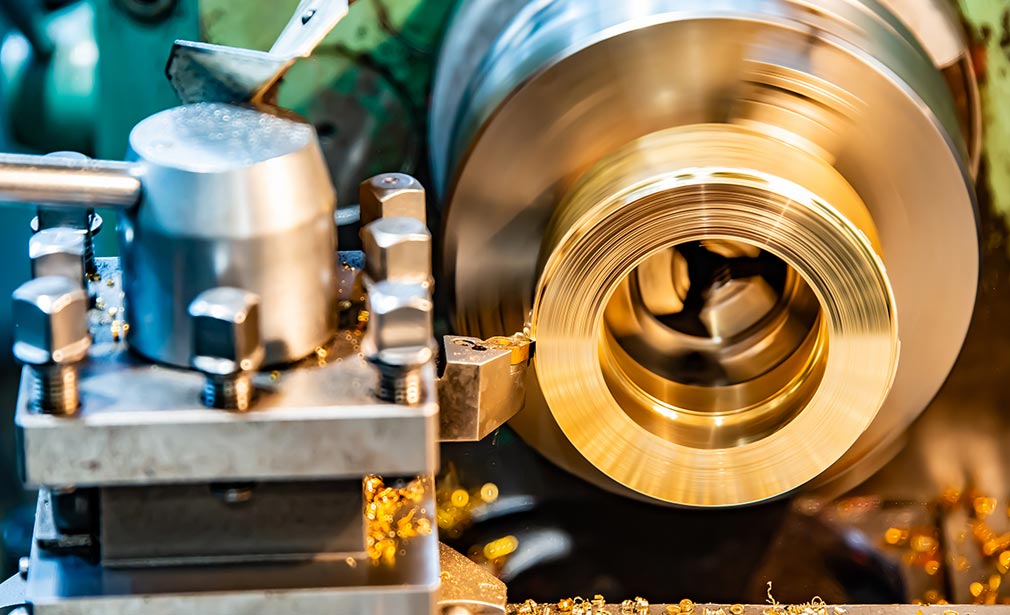

What is CNC Turning?

Also known as lathe, CNC turning is a machining process where a lathe, controlled by a computer that moves automatically based on coded instructions, is used to create cylindrical components by removing material from a workpiece. It is a precise machining operation that shapes the desired object out of a material by removing the unwanted parts. Materials commonly used are metal, wood or plastic, and CNC turning is used frequently in the automotive, aerospace, medical, and manufacturing industries where high-quality components are produced for various applications.

One of the main advantages of using a CNC turning is its accuracy and consistency in producing precise parts. The computer program-controlled movement of the cutting tools ensures that parts are made with a high degree of precision essential for industries that require strict tolerance for parts and prototypes. Once the computer program is set up, the machine can run continuously, producing parts in a fraction of the time it would take a manual operator. That means increased productivity and lower production costs.

Here's an overview of the lathe process:

- 1. Workpiece Setup: The workpiece, which can be a cylindrical or rod-shaped object, is securely mounted in the lathe machine. It is held in place by fixtures such as chucks, collets, or centers, depending on the type of lathe and the workpiece's characteristics.

- 2. Tool Selection: The appropriate cutting tool is selected based on the desired shape, material, and machining requirements. Cutting tools for lathe typically consist of a replaceable insert made of carbide, ceramic, or high-speed steel.

- 3. Tool Positioning: The cutting tool is positioned in the tool post of the lathe machine. The tool post allows for precise adjustment of the tool's position relative to the workpiece.

- 4. Spindle Speed and Feed Rate Setup: The lathe machine's spindle speed and feed rate are set based on factors such as the workpiece material, desired surface finish, and the type of machining operation (e.g., roughing or finishing). Higher spindle speeds are generally used for smaller-diameter workpieces or when a smoother finish is required.

- 5. Machining Operations: Once the lathe machine is set up, the machining operations begin. The workpiece rotates, and the cutting tool is brought into contact with the rotating workpiece to remove material and shape it. The specific operations performed during lathe depend on the desired outcome but can include:

- Facing: Removing material from the end face of the workpiece to create a flat surface.

- Turning: Removing material from the outer surface of the workpiece to create a cylindrical shape.

- Tapering: Gradually reducing the diameter of the workpiece along its length to create a tapered shape.

- Threading: Cutting threads into the workpiece to create external or internal screw threads.

- Grooving: Cutting grooves or recesses on the surface of the workpiece.

- 6. Monitoring and Adjustments: Throughout the lathe process, the machinist monitors the machining parameters, such as tool wear, surface finish, and dimensional accuracy. Adjustments may be made to the cutting speed, feed rate, or tool position as necessary to ensure the desired outcome.

- 7. Finishing and Inspection: Once the lathe operations are complete, the workpiece may undergo additional finishing operations, such as polishing or deburring, to achieve the desired surface quality. The finished workpiece is then inspected for dimensional accuracy, surface finish, and adherence to specifications.

It’s important to note that lathe is a versatile process that can be performed on various materials, including metals, plastics, and wood. The specific parameters and techniques used in lathe may vary depending on the material being machined and the desired outcome.

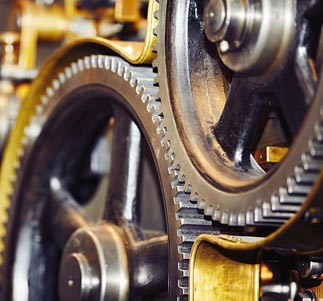

Applications for CNC Turning

CNC turning can be used in a variety of industries, including aerospace, automotive, and manufacturing. They can create a wide range of parts, from simple cylindrical shapes to intricate designs with multiple layers and contours.

01

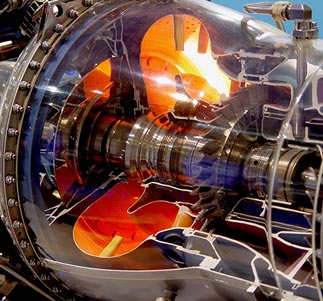

Aerospace

02

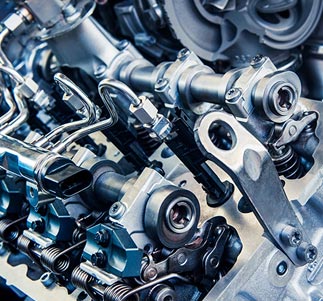

Automotive

03