Precision Machining Quality and Inspection

Quality Inspection are crucial aspects of CNC machining. Radian Machining takes quality control and inspection seriously to guarantee customer satisfaction and product excellence. Design specifications are meticulously reviewed before the manufacturing process to ensure the quality of the work. This initial step is crucial in preventing errors and ensuring that the final products meet the customer’s requirements.

During the CNC machining process, our operators closely monitor production to ensure that machining operations are performing properly. Our CNC machines and precision machining tools are designed for the production of high-quality components with tight tolerances.

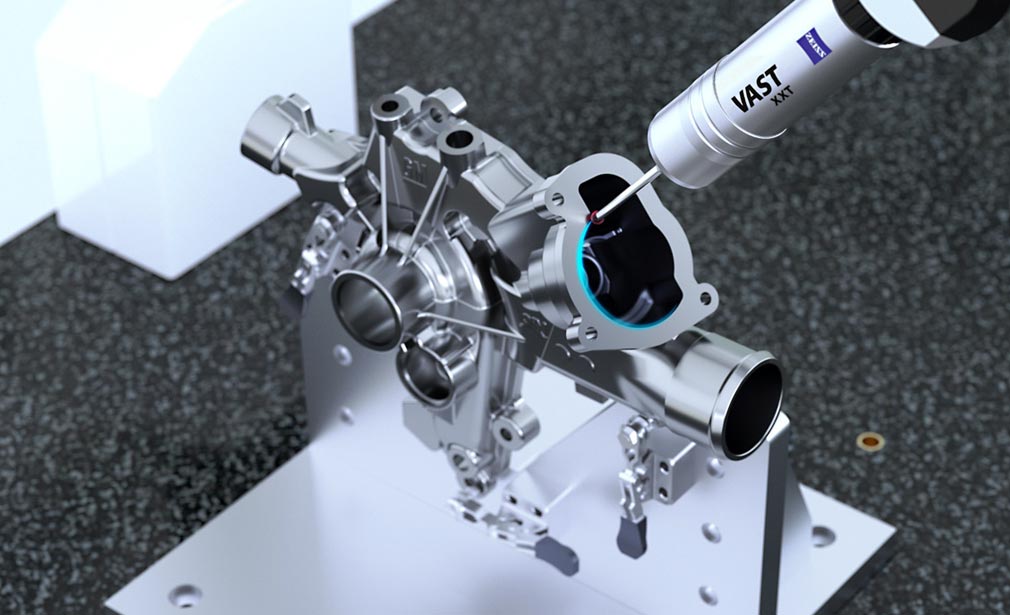

Quality Inspection: After the completion of the machining process, our quality control team conducts thorough inspections and tests on the finished products. We use a variety of quality inspection tools, such as coordinate measuring machines (CMM), optical comparators, and surface roughness testers, to verify the dimensional accuracy and surface finish of the parts.

We also conduct functional testing to ensure that the parts perform as intended and meet the required performance standards. Our quality control follows strict protocols and quality assurance procedures to identify any potential defects or issues to address them promptly.

Our temperature and humidity controlled QA lab is equipped with the following inspection equipment:

- Zeiss CMM

- Tin Coated Thread Gages

- Height Stands

- Surface Plates

- Dial Indicators

- Calipers

- Micrometers

- Gage Pins